Options

Cabinet MOC

|

FM compliant plastics, or other

according to customer requirements |

| Sample chamber |

For on line sampling |

| Filter housing(s) sized |

According to process requirements |

| Stirrer |

Stirrer and pneumatic motor for the |

| Suppressor |

For delivery pumps |

| H2O2 Analyzer |

|

|

|

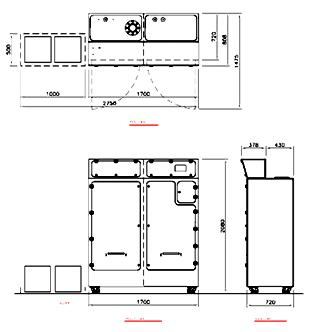

Dimensions

|

|

Height

|

Width

|

Depth

|

|

Process cabinet

|

2,080 mm

|

1,700 mm

|

720 mm

|

|

Analyzer cabinet *

|

2,080 mm

|

600 mm

|

720 mm

|

* Optional

Utilities Needed

| N2 |

1 m3/hr. at 2 bar |

| CDA |

10 m3/hr. At 5-7 bar |

| Exhaust |

500 m3/hr |

| Drain |

10 l/min. (top connection) |

System Delivery Volumes

Output Up to 30 lpm as required by the application

|

|