Options

External pump cabinet To allow chemical delivery when

tool is located on CDU level

Cabinet MOC Stainless steel frame, coated

FM compliant plastics

Delivery / Batch tank Consult our factory for sizes

Sample chamber for on line sampling

Filter housing according to process requirements

Utilities Needed

N2 30 psi, 20 lpm

CDA 80-100 psi, up to 50 lpm

Exhaust 250 m3/h

DI supply 30 psi, up to 5 lpm

Main power 24 VDC, 10 Amp

Drain ½” PFA max flow 15 lpm

Construction Materials

Std CDU White PP or other, on a coated

stainless steel chassis

Tubing HP PFA

Valves HP PFA

Pumps PTFE / HP440 PFA

|

|

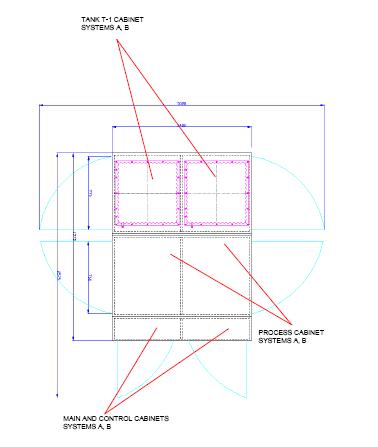

Dimensions

| |

Height |

Width |

Depth |

| Process cabinet (2 Sides) |

2,080 mm |

1,480 mm |

1,975 mm |

| External pump cabinet |

1,500 mm |

780 mm |

378 mm |

Electrical- top location

Supply 24 VDC, 10 Amp

Electrical protection 16 Amp

PLC ABB

Touch Screen Exter

System Delivery Volumes

Up to 450 Liters batch volume. Circulation output up to 30 lpm

As required by the application.

|

|

|