|

|

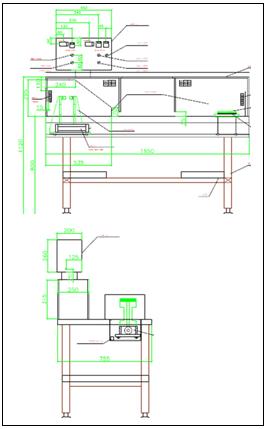

Dimensions

| |

Height |

Width |

Depth |

| General |

1,120 mm |

1,650 mm |

755 mm |

Utilities Needed

Gas N2 Flow 50 lpm Max.

Gas N2 Pressure60 psi

Electrical

Supply 220 VAC 6A

Construction Materials

Frame structure Aluminum

Work Wood Surface coating with HPL antistatic surface

Gas Chamber Perspex

Heating plate Aluminum

Hot clamp Aluminum

|